Yeah – we refresh wood furniture too.

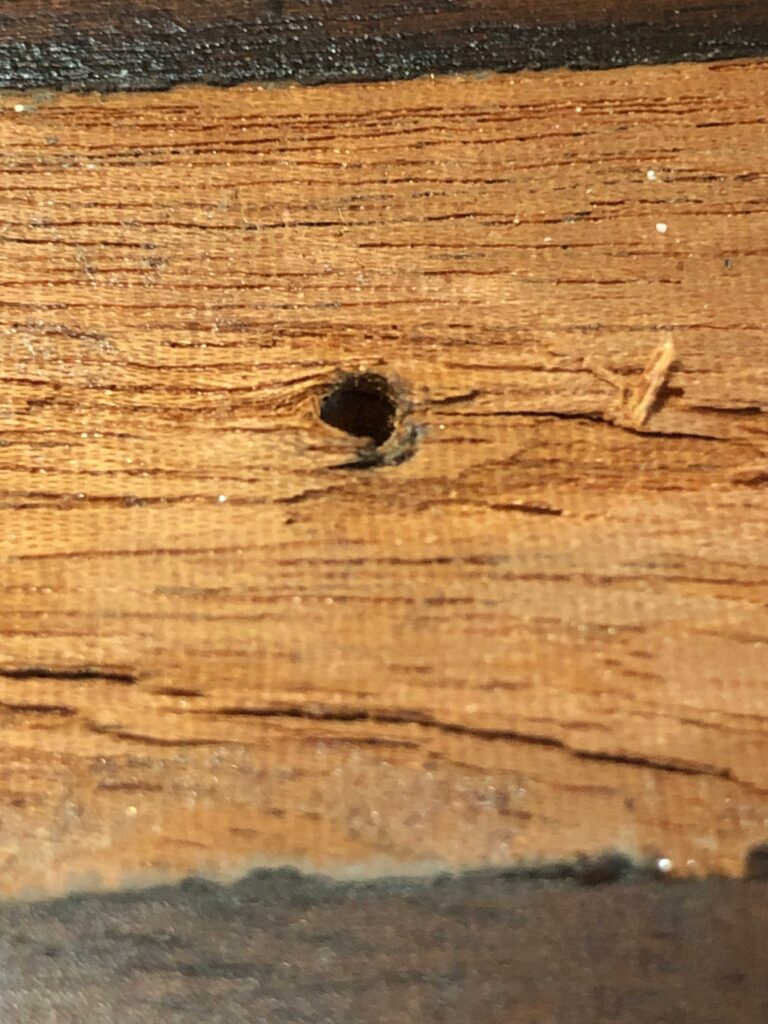

After decades of great service – this pair of Henkel Harris Dining Chairs needed some love. It was nothing major. On both, the glue had failed where the seat meets the back – and the chairs had become loose and quite wobbly. The support screws holding the back to the seat had been tightened as far as they would go – and they eventually stripped out of the wood.

The backs were gently removed from the seats, the screw holes were rebuilt and filled completely with new wood, and sanded smooth. The old glue was removed and new glue was applied to the dowels, which were still in very good condition. The seats and backs were rejoined, and at last check, they were back in service around the dining room table.

Another wrought iron, steel, metal glider rocking chair has been returned to service! I love saving these old chairs.

Outdoor patio furniture that is made to last – but still needs some help every now and then. Both upper corner joints needed to be rebuilt, where new solid steel inserts are fabricated and joined to the rear of the chair. The broken joints are then blended into the inserts, creating a durable repair that hopefully will outlast the life of the chair.

This is a very common area for damage on these chairs – and I’m glad I’ve developed a great solution for bringing them back to life. Hopefully to be enjoyed for years to come!

For a more in-depth explanation of the repair process – see this link:

Repairing old Wrought Iron – Steel Patio Gliders, Rockers and Deck Chairs.